ENVIRONMENT TEST

Do You Know the Standards and Evaluation Methods for Salt Spray Tests?

The salt spray test is an environmental test designed to assess the corrosion resistance of products or metal materials. It involves creating an artificial salt spray environment using specialized equipment. There are two primary categories of salt spray testing:

Natural Exposure Tests - Rarely performed due to the long duration and labor involved.

Artificial Accelerated Salt Spray Tests - A faster and more controlled method. Here, a saltwater solution is atomized and sprayed in a closed, temperature-controlled chamber. By observing the changes in the sample over time, the corrosion resistance is assessed.

Principles of the Salt Spray Test

Corrosion in most metals occurs in atmospheric conditions containing oxygen, humidity, and other corrosive factors. Salt spray corrosion, one of the most common and destructive forms, involves electrochemical reactions. Chloride ions, highly penetrating and capable of displacing protective oxide layers, play a significant role in this process, leading to material degradation.

Types of Salt Spray Tests

Neutral Salt Spray Test (NSS)

Uses a 5% sodium chloride solution at a neutral pH (6.5–7.2).

Operates at 35°C with a salt deposition rate of 1–2 ml/80 cm² per hour.

Suitable for metals, alloys, conversion coatings, and anodized films.

Acetic Acid Salt Spray Test (AASS)

Involves adding acetic acid to adjust the solution to an acidic pH (3.1–3.3).

Accelerates corrosion three times faster than NSS.

Often used for decorative coatings like copper-nickel-chromium or anodized aluminum.

Copper-Accelerated Acetic Acid Salt Spray Test (CASS)

Includes copper chloride (CuCl₂) to enhance corrosion.

Corrosion rate is eight times faster than NSS.

Suitable for evaluating high-performance decorative coatings.

Cyclic Salt Spray Test

Combines salt spray with alternating humidity cycles.

Commonly used for complex products where internal and external corrosion needs assessment.

Evaluation Methods

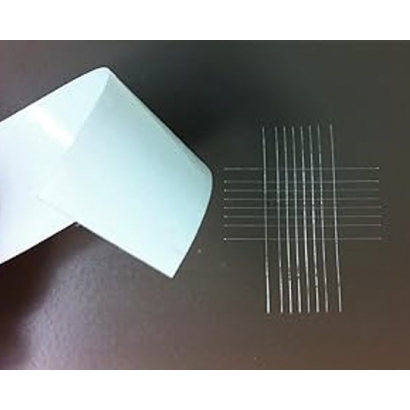

Grading Method: Evaluates the ratio of corroded to total surface area.

Weight Loss Method: Measures the weight difference before and after testing to determine material degradation.

Visual Inspection: Assesses the presence of corrosion visually, often used in product standards.

Statistical Analysis: Provides confidence levels for data and trends in corrosion resistance.

Common Standards for Salt Spray Tests

GB/T 10125-2021: Artificial Atmosphere Corrosion Test.

GB/T 2423.17-2008: Environmental Testing for Electrical Products.

IEC 60068-2-11: Salt Spray Testing for Electronic Products.

GJB 150.11A-2009: Salt Spray Testing for Military Equipment.

Factors Affecting Test Results

Salt solution concentration

Temperature and humidity

Sample placement angle

Spraying method

Test duration and interruptions

Natural Exposure Tests - Rarely performed due to the long duration and labor involved.

Artificial Accelerated Salt Spray Tests - A faster and more controlled method. Here, a saltwater solution is atomized and sprayed in a closed, temperature-controlled chamber. By observing the changes in the sample over time, the corrosion resistance is assessed.

Principles of the Salt Spray Test

Corrosion in most metals occurs in atmospheric conditions containing oxygen, humidity, and other corrosive factors. Salt spray corrosion, one of the most common and destructive forms, involves electrochemical reactions. Chloride ions, highly penetrating and capable of displacing protective oxide layers, play a significant role in this process, leading to material degradation.

Types of Salt Spray Tests

Neutral Salt Spray Test (NSS)

Uses a 5% sodium chloride solution at a neutral pH (6.5–7.2).

Operates at 35°C with a salt deposition rate of 1–2 ml/80 cm² per hour.

Suitable for metals, alloys, conversion coatings, and anodized films.

Acetic Acid Salt Spray Test (AASS)

Involves adding acetic acid to adjust the solution to an acidic pH (3.1–3.3).

Accelerates corrosion three times faster than NSS.

Often used for decorative coatings like copper-nickel-chromium or anodized aluminum.

Copper-Accelerated Acetic Acid Salt Spray Test (CASS)

Includes copper chloride (CuCl₂) to enhance corrosion.

Corrosion rate is eight times faster than NSS.

Suitable for evaluating high-performance decorative coatings.

Cyclic Salt Spray Test

Combines salt spray with alternating humidity cycles.

Commonly used for complex products where internal and external corrosion needs assessment.

Evaluation Methods

Grading Method: Evaluates the ratio of corroded to total surface area.

Weight Loss Method: Measures the weight difference before and after testing to determine material degradation.

Visual Inspection: Assesses the presence of corrosion visually, often used in product standards.

Statistical Analysis: Provides confidence levels for data and trends in corrosion resistance.

Common Standards for Salt Spray Tests

GB/T 10125-2021: Artificial Atmosphere Corrosion Test.

GB/T 2423.17-2008: Environmental Testing for Electrical Products.

IEC 60068-2-11: Salt Spray Testing for Electronic Products.

GJB 150.11A-2009: Salt Spray Testing for Military Equipment.

Factors Affecting Test Results

Salt solution concentration

Temperature and humidity

Sample placement angle

Spraying method

Test duration and interruptions