ASSEMBLY METHOD

What is about Ultrasonic welding

Ultrasonic welding is a widely used technology in the manufacturing process of automotive lights. This technique uses high-frequency ultrasonic vibrations to fuse two plastic parts together, creating a strong bond. Here is some relevant knowledge about ultrasonic welding for automotive lights:

Principle

Ultrasonic welding uses high-frequency ultrasonic vibrations (typically between 20 kHz and 40 kHz) to transfer energy to the contact surfaces of the plastic parts to be joined. Under the action of high-frequency vibrations, the plastic contact surfaces generate localized high temperatures, causing the material to melt and fuse. When the vibrations stop, the melted material cools and solidifies, forming a strong bond.

Advantages

Speed and Efficiency: The ultrasonic welding process is usually completed within seconds, making it suitable for mass production.

High Strength: The joints formed have high mechanical strength and can withstand significant external forces.

No Additional Materials: No adhesives or other auxiliary materials are needed, reducing costs and the risk of material contamination.

High Precision: It enables high-precision bonding, suitable for complex and fine components.

Environmentally Friendly: Ultrasonic welding does not produce harmful gases, making it environmentally friendly.

Applications

Ultrasonic welding is widely used in the assembly of various plastic parts in automotive lights, such as:

Bonding Lenses and Housings: Joining transparent or semi-transparent lenses to the housing.

Fixing Lenses and Reflectors: Securing optical lenses and reflectors in place.

Assembling Internal Components: Securing internal brackets, heat sinks, and light guides.

Material Requirements

Ultrasonic welding is mainly suitable for thermoplastic materials, such as:

Polycarbonate (PC)

Polymethyl Methacrylate (PMMA)

Polypropylene (PP)

Acrylonitrile Butadiene Styrene (ABS)

These materials can melt and fuse under ultrasonic vibrations to form a strong bond.

Operating Steps

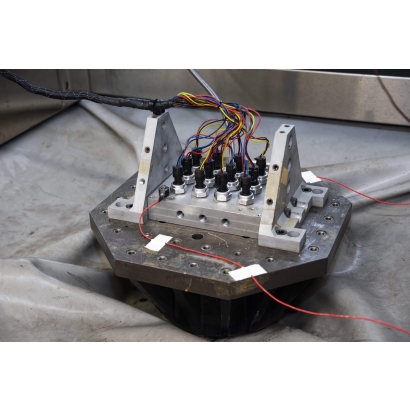

Prepare the Workpieces: Place the plastic parts to be joined in the ultrasonic welding machine's fixture.

Set Parameters: Set the ultrasonic welding machine parameters, such as vibration frequency, amplitude, welding time, and pressure.

Start Welding: Start the ultrasonic welding machine to begin the welding process.

Cool and Remove: After welding is complete, allow the material to cool and solidify, then remove the bonded workpieces.

Maintenance and Inspection

Regular Equipment Checks: Regularly check the components of the ultrasonic welding machine to ensure normal operation.

Clean the Welding Head: Regularly clean the welding head to avoid contaminants affecting welding quality.

Test Bond Strength: Regularly perform bond strength tests to ensure welding quality meets requirements.

Summary

Ultrasonic welding technology offers significant advantages in automotive light manufacturing, such as speed, efficiency, high strength, and high precision. By choosing the right materials and operating parameters, ultrasonic welding can achieve high-quality bonds, meeting the stringent requirements of automotive light manufacturing.

Principle

Ultrasonic welding uses high-frequency ultrasonic vibrations (typically between 20 kHz and 40 kHz) to transfer energy to the contact surfaces of the plastic parts to be joined. Under the action of high-frequency vibrations, the plastic contact surfaces generate localized high temperatures, causing the material to melt and fuse. When the vibrations stop, the melted material cools and solidifies, forming a strong bond.

Advantages

Speed and Efficiency: The ultrasonic welding process is usually completed within seconds, making it suitable for mass production.

High Strength: The joints formed have high mechanical strength and can withstand significant external forces.

No Additional Materials: No adhesives or other auxiliary materials are needed, reducing costs and the risk of material contamination.

High Precision: It enables high-precision bonding, suitable for complex and fine components.

Environmentally Friendly: Ultrasonic welding does not produce harmful gases, making it environmentally friendly.

Applications

Ultrasonic welding is widely used in the assembly of various plastic parts in automotive lights, such as:

Bonding Lenses and Housings: Joining transparent or semi-transparent lenses to the housing.

Fixing Lenses and Reflectors: Securing optical lenses and reflectors in place.

Assembling Internal Components: Securing internal brackets, heat sinks, and light guides.

Material Requirements

Ultrasonic welding is mainly suitable for thermoplastic materials, such as:

Polycarbonate (PC)

Polymethyl Methacrylate (PMMA)

Polypropylene (PP)

Acrylonitrile Butadiene Styrene (ABS)

These materials can melt and fuse under ultrasonic vibrations to form a strong bond.

Operating Steps

Prepare the Workpieces: Place the plastic parts to be joined in the ultrasonic welding machine's fixture.

Set Parameters: Set the ultrasonic welding machine parameters, such as vibration frequency, amplitude, welding time, and pressure.

Start Welding: Start the ultrasonic welding machine to begin the welding process.

Cool and Remove: After welding is complete, allow the material to cool and solidify, then remove the bonded workpieces.

Maintenance and Inspection

Regular Equipment Checks: Regularly check the components of the ultrasonic welding machine to ensure normal operation.

Clean the Welding Head: Regularly clean the welding head to avoid contaminants affecting welding quality.

Test Bond Strength: Regularly perform bond strength tests to ensure welding quality meets requirements.

Summary

Ultrasonic welding technology offers significant advantages in automotive light manufacturing, such as speed, efficiency, high strength, and high precision. By choosing the right materials and operating parameters, ultrasonic welding can achieve high-quality bonds, meeting the stringent requirements of automotive light manufacturing.