All PRODUCTS

-

Read More

How to increase the reflectance value of reflectors?

How to increase the reflectance value of reflectors?How to increase the reflectance value of reflectors?

How to increase the reflectance value of reflectors?

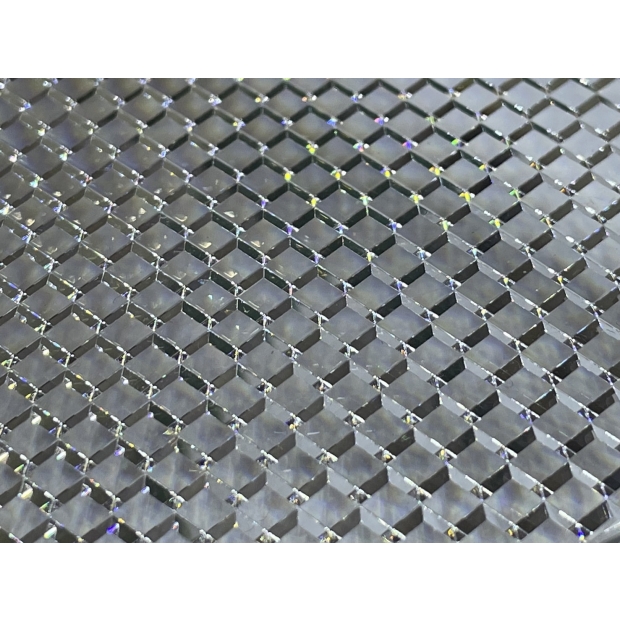

In addition using high reflective electroform insert , factors such as the mold material, mold surface finish, and adjustments to the injection molding machine also affect the reflector's reflectance value. To increase the reflectance value of the reflector, you can try the following approaches.

1

1. The height of the electroform core (tooth peak to the flat bottom of the mold core) is about 10mm (the height of the mold core seat is determined according to the mold design)

2. It is recommended that the material of the cavity mold should be P5 or above, BPMHH2738C or high nickel content and high hardness steel is better!

3. The cavity mold polished required to be applied by hand to ensure smoothness and precision, and the polishing is required to be above #3000!

4. The average thickness of the reflector (tooth tip to mother die surface) is recommended to be 1.3 ~ 1.5mm!

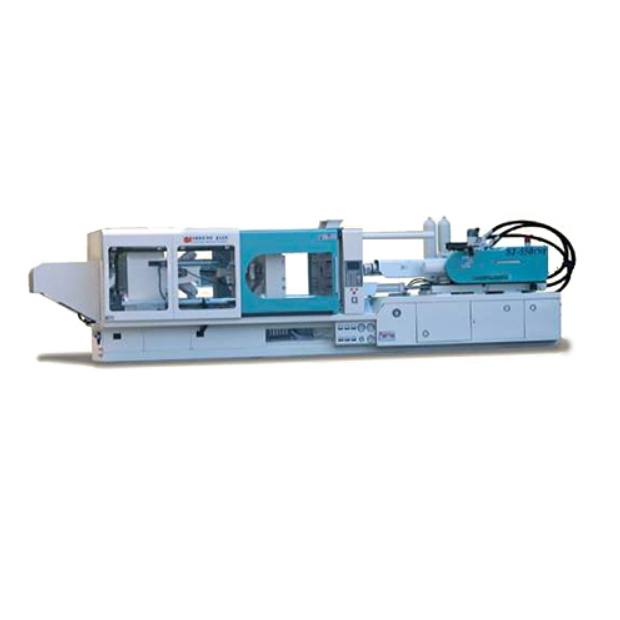

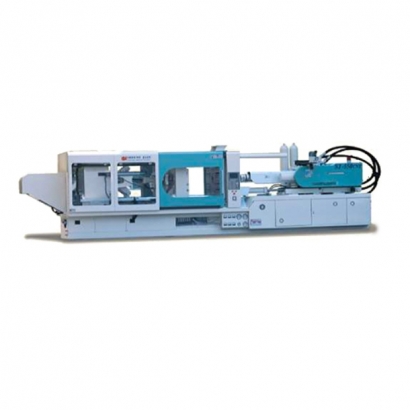

5. The mass production must be produced with a mold temperature machine during injection molding (it is recommended that the mold temperature be set above 80 degrees C)!

The reference temperature of the material tube depending on the machine conditions, high temperature is still recommended

PC∕PMMA material temperature: 200~240 degrees Celsius is recommended (depending on machine conditions but still high temperature is better)

6. Be careful not to cause electroform to be scratched by the injection of cold material (cannot be repaired)

7. If need a release agent to help release the mold during injection molding, please use a water-based release agent to avoid affecting the light distribution.

8. When the mold is sealed, the electroform core should be sprayed with vaporized spray (do not use emulsified maintenance oil)

And before the next production, it must be cleaned with solvent before starting injection molding

9. The cleaning of electroform can be immersed in acetone or scrubbed with a brush (brown) on the tooth surface with acetone-free cleaning agent.

-

Read More

Precautions for plastic injection reflector

Precautions for plastic injection reflectorPrecautions for plastic injection reflector

Precautions for plastic injection reflector

The following points should be paid attention for the electroforming mold of the reflector:

1. The height of the electroform core (tooth peak to the flat bottom of the mold core) is about 10mm (the height of the mold core seat is determined according to the mold design)

2. It is recommended that the material of the cavity mold should be P5 or above, BPMHH2738C or high nickel content and high hardness steel is better!

3. The cavity mold polished required to be applied by hand to ensure smoothness and precision, and the polishing is required to be above #3000!

4. The average thickness of the reflector (tooth tip to mother die surface) is recommended to be 1.3 ~ 1.5mm!

5. The mass production must be produced with a mold temperature machine during injection molding (it is recommended that the mold temperature be set above 80 degrees C)!

The reference temperature of the material tube depending on the machine conditions, high temperature is still recommended

PC∕PMMA material temperature: 200~240 degrees Celsius is recommended (depending on machine conditions but still high temperature is better)

6. Be careful not to cause electroform to be scratched by the injection of cold material (cannot be repaired)

7. If need a release agent to help release the mold during injection molding, please use a water-based release agent to avoid affecting the light distribution.

8. When the mold is sealed, the electroform core should be sprayed with vaporized spray (do not use emulsified maintenance oil)

And before the next production, it must be cleaned with solvent before starting injection molding

9. The cleaning of electroform can be immersed in acetone or scrubbed with a brush (brown) on the tooth surface with acetone-free cleaning agent. -

Read More

The Maintenance Steps Of Electroform

The Maintenance Steps Of ElectroformThe Maintenance Steps Of Electroform

Description

When electroform is injection-molded, the LENS might oxidize due to oil stains and other impurities, and the non-glossy oxides will be generated on the electroform, which will lead to rust or oxidation. Maintenance work can extend life of electroform.

Maintenance on the Mold

a. Before injection molding, please use an air gun to spray the surface of the electroform to remove oil, impurities or foreign matter.

b. Then use organic solvent (acetone, stain removal oil) and brush to remove rust-proof oil.

c. Finally, spray the surface with air gun, and check whether there are oil stains or foreign matter residues on each reflective surface, prevent scratches, adhesion or oxidation on the surface due to oil stains or residues after injection molding.And do not perform molding work until the anti-rust oil has been completely removed.

d. After the injection molding is completed, spray the residual material on the surface with air gun, and then clean the surface of the electroform mold core with acetone or degreasing oil.

e. After the final spraying of vaporized anti-rust oil, store the mold to avoid rusting.Do not use white emulsified mold maintenance spray

Note: Do not use chloride ions (mold lotion, WD40 and other organic solvents) to clean electroform to prevent serious corrosion.

Cleaning methods and instructions

a. Use the back end of paint brush, as shown below

Cut off the softer bristles at the end and cut them to flat, use the hard at the root to apply.

b. When cleaning, please use air gun to clean the surface, avoid scratching the surface of the electroform due to residues, impurities or dirt during brushing.

c. Soaking in toluene: When the surface of the electroform is dirty and cannot be cleaned by the above two methods, it can be soaked and dissolved in toluene for a long time.

Note: Acetone or toluene are high volatile agents. When using it, any fireworks must be strictly prohibited, and electrical appliances must be turned off.

The problem that the grease and dirt

are not removed after heating

Oil will damage the electroform and even penetrate into the Ni layer to produce non-glossy oxides and cause rust. The surface is uneven, and cannot be repaired.

Oil stains on the surface of PIN become oxides and carbides

Reflector with Oil

Mixing of plastic and impurities scratches the reflective surface and affects the reflection value

-

Read More

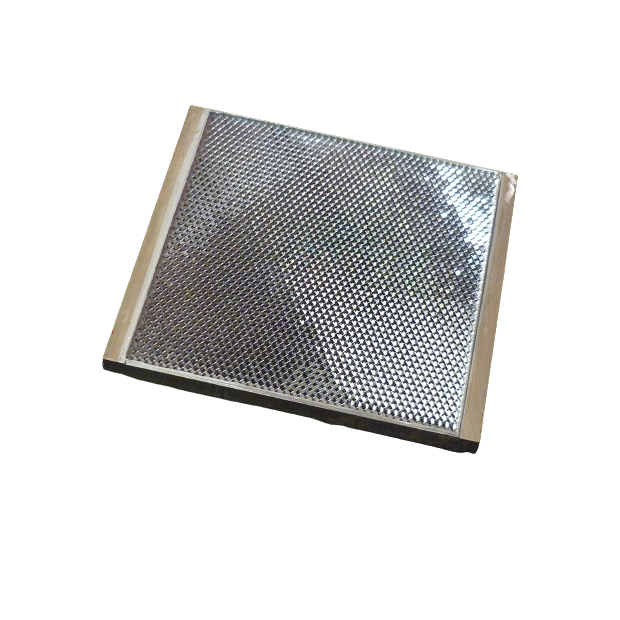

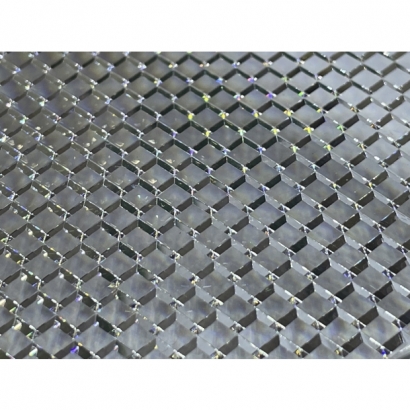

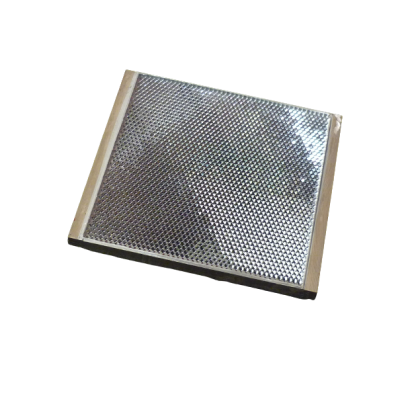

Standard Flat Electroform

Standard Flat ElectroformStandard Flat Electroform

electroformado

Elektroformierung

elektroformovanie

elektroformování

ECE / SAE

Certificate -

Read More

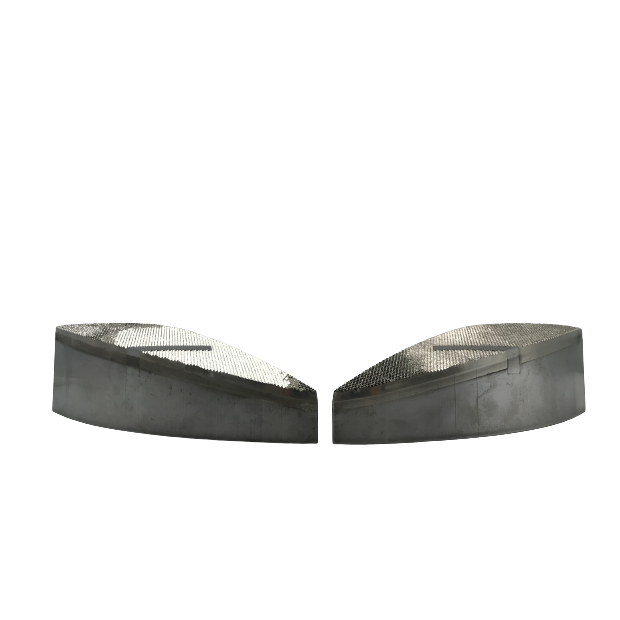

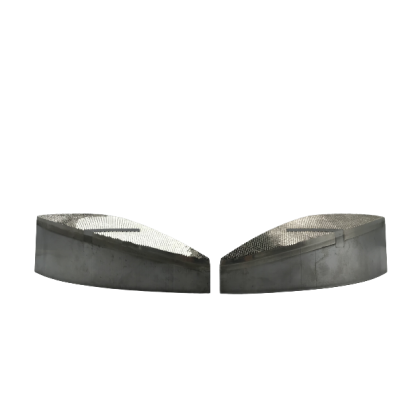

Customized Curve Electroform

Customized Curve ElectroformCustomized Curve Electroform

Personalizado

Maßgeschneidert

Prispôsobený

Přizpůsobený

ECE / SAE

Certificate -

Read More

M404 License Plate Light

M404 License Plate LightM404 License Plate Light

License Plate Light

Luz de Matrícula

Fit motorcycle, electric motorcycle, scooter, sportbikes

ECE Certificated -

Read More

M405 License Plate Light

M405 License Plate LightM405 License Plate Light

ナンバープレートライト

Kennzeichenleuchte

Fit motorcycle, moterbike, scooter, dirtbike

ECE Certificated -

Read More

M406 License Plate Light

M406 License Plate LightM406 License Plate Light

Osvetlenie ŠPZ

Osvětlení SPZ

Fit motorcycle, E-motorcycle, scooter, Escooter

ECE Certificated -

Read More

M409 License Plate Light

M409 License Plate LightM409 License Plate Light

License Plate Light

Luz de Matrícula

Fit motorcycle, electricvehicle, scooter, touring motorcycle

ECE Certificated -

Read More

M413 License Plate Light

M413 License Plate LightM413 License Plate Light

ナンバープレートライト

Kennzeichenleuchte

Fit motorcycle, moterbike, scooter, off-road motorcycle

ECE Certificated -

Read More

M101 Motorcycle Tail Light

M101 Motorcycle Tail LightM101 Motorcycle Tail Light

Motorcycle Tail Light

Luz Trasera de Motocicleta

Fit motorcycle, electric motorcycle, scooter, dirtbike

ECE Certificated -

Read More

M103 Motorcycle Tail Light

M103 Motorcycle Tail LightM103 Motorcycle Tail Light

オートバイのテールライト

Motorrad Rücklicht

Fit motorcycle, scooter, electricvehicle, sportbikes

ECE Certificated