The production of reflector is using electroform insert mold doing plastic injection ; the quality of electroform insert mold will determined the reflector can achieve the purpose of warning or not.

Mastering in PIN polished、PIN arrangement and Electroform technology will be an important point to producing high-quality electroform insert , it is also a technical threshold that is difficult to overcome.

FORUP is one of the few electroform insert mould suppliers in the world, we have more than 10 years of electroform insert mould evaluation and production experience, continue to improve our technology, we are proud to provide the highest quality electroform insert mould , once the case undertake,we will ensure comply the certificate.

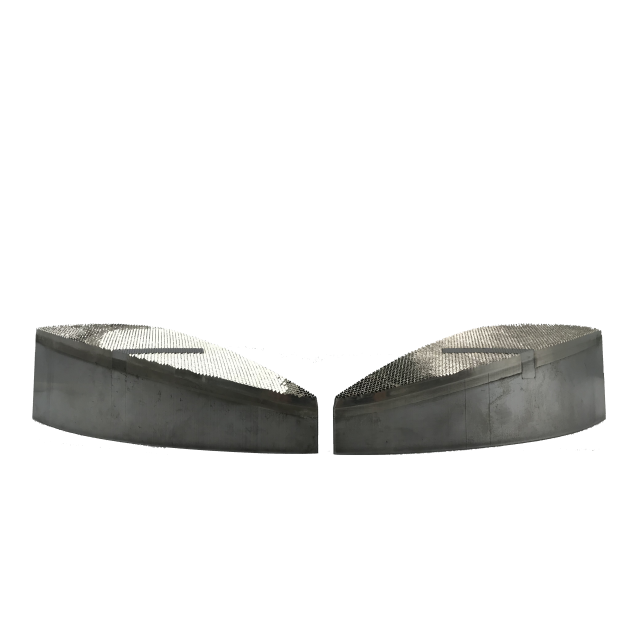

- Customized Curve Electroform

- Mould Production

- Mass Production

We cautiously evaluate each reflector electroform development case, and provide free feasibility evaluation services. FORUP will comprehensively analyze various conditions, including reflect area, regulations that need to comply, and product installation location etc.

Through preliminary analysis, blind spots can be found in advance, and the situation that the product cannot pass the regulations can be ruled out.

For reflector electroform mold insert development requirements, please click and complete the Feasibility Form below ,contact sales@foruplight.com, we will immediately evaluate and submit a report.

FORUP design team is able to build the corresponding electroforming 3D model or Complete mold data according to the 3D CAD or 2D Drawing of product. FORUP provide the serice to make insert and mold.

Nickel will be electro-deposited on the PIN assembly plate according to PIN's accurate geometry. The electroplating process requires 3-5 weeks to obtain a 10 mm-12 mm thickness of Nickel.

FORUP owns the technique of whole processing form PIN Processing and Polishing to electroforming. With those well polished fine PINs as master material to accomplish the high performance reflective Reflex Electroform.

The roughness of polished PIN's surface can be under 0.1um.

- Use 2.38 mm hexagonal pin

- Comply with modern aesthetic design

- Exclusive polishing technology, excellent reflection performance

According to the pre-established 3D model, the PIN will arrangement and fixation for the next electrofor step.

Nickel was formed during the electroforming reaction and deposited on the PIN, reproducing the hexagonal shape.

This process is rather slow, about 3-5 weeks to form 10mm of nickel.

Upon finishing the electroform, the entire mold is formed according to the mold-status 3D CAD provided by our customers. We value each detail on the mold, including NC processing, drilling holes, precision and water line for cooling etc.

When electroform completed, the final confirmation will be carried out according to the appearance, the optic value will be examined to ensure that the output is perfect electroform.