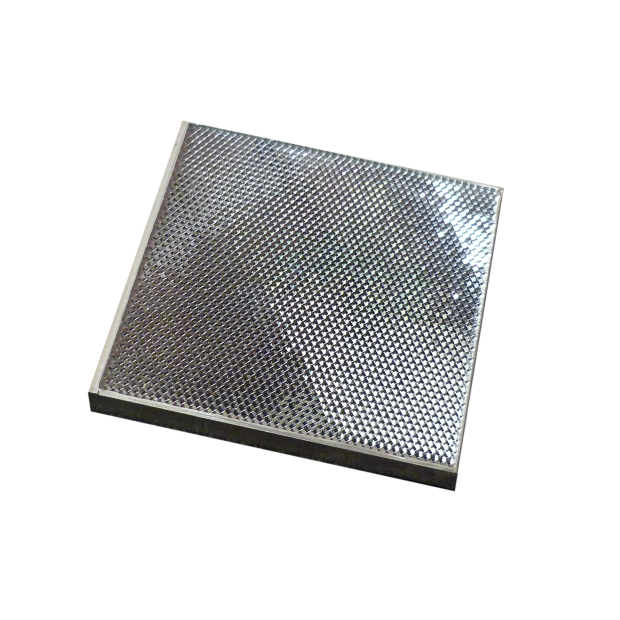

The production of reflector is using electroform insert mold doing plastic injection ; the quality of electroform insert mold will determined the reflector can achieve the purpose of warning or not.

Mastering in PIN polished、PIN arrangement and Electroform technology will be an important point to producing high-quality electroform insert , it is also a technical threshold that is difficult to overcome.

FORUP is one of the few electroform insert mould suppliers in the world, we have more than 10 years of electroform insert mould evaluation and production experience, continue to improve our technology, we are proud to provide the highest quality electroform insert mould , once the case undertake,we will ensure comply the certificate.

- Standard Flat Electroform (100 * 100 mm)

- Back Plate design and assembly

- Wire Electrical Discharge Machining service

FORUP provides Wire Electrical Discharge Machining service, which can cut the electroform insert into any shape according to the customized requirements. Cutting along the shape of the hexagonal PIN will not destroy the entire PIN, not only maintain the complete appearance, but also maximize the reflection value in the limited reflection area.

Through more than ten years of experience in the electroform, we have the ability to make the most appropriate combination of electroform, reduce remainder, and save the development cost.

Upon finishing the electroform, the entire mold is formed according to the mold-status 3D CAD provided by our customers. We value each detail on the mold, including NC processing, drilling holes, precision and water line for cooling etc.